CARRYING OUT MAINTENANCE? DON’T FORGET TO CARRY OUT A FILTER CHANGE!

NEW PANCLEAN FILTERS FOR A CLEAN AND SAFE CAB NOW AVAILABLE FROM GRANIT

The annual maintenance period is upon us once more. Do you offer cab filter changes as part of your maintenance programme? Next to oil changes and air conditioning servicing, checking the cab filters in tractors and construction machinery is a key part of the annual vehicle service. This is because cab filters have the important job of purifying the surrounding air before it enters the cab.

The contaminants and pollutants encountered in the agriculture sector mean that regular cab filter changes are essential to ensure a safe working environment. Another problem is that tractor cabs tend to only be fitted with standard filters. These only filter out unpleasant odours and airborne particles such as dust and pollen, but the amount of pollutants in the breathable air remains high. Higher-quality filters made of materials such as activated carbon also remove pollutants and noxious gases. This prevents pesticides and fungicides from entering the cab unchecked during work in the field.

Did you know that activated carbon filters should be changed annually?

Standard cab filters should be changed after 500 operating hours. Activated carbon filters come to the end of their life after a year when the filter performance significantly decreases and dirt particles, pollutants and noxious gases can no longer be filtered out, which can be dangerous for the driver.

PURIFY THE AIR IN THE CAB WITH MULTI-LAYER FILTERS FROM PANCLEAN

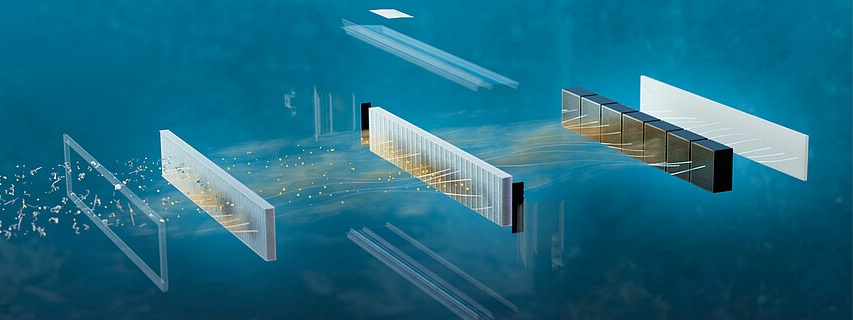

We are pleased to offer a wide range of products from European cab filter experts Panclean. The Italian original equipment manufacturer produces all of its filters in Europe and carries out extensive quality checks at all stages of the production process, from the production of individual components right through to the finished product. Standard, pollen and dust filters, plus three-layer activated carbon filters capable of filtering airborne particles, aerosols and vapours can be found in the GRANIT webshop. You are guaranteed to find suitable products for all common manufacturers and machine types.

Check out our extensive Panclean range in the GRANIT webshop now, and share the benefits of a cab filter change with your customers.

Here are a few more tips for working with cab filters

- Never use compressed air to clean contaminated filters! This may damage the filters, meaning that the filter performance is no longer guaranteed.

- Do not wash contaminated cab filters! This can also lead to damage.

- Never shake or knock out! Pollutants in the filter could be released and inhaled.

- Contaminated cab filters should never be installed! Filter performance would no longer be guaranteed.

- Cab filters should not be used beyond the expiry date! Filter performance decreases significantly as a result of contamination.

Recommendations

We are here for you!

Our customer and repair services, marketing support and efficient logistics solutions make us a strong partner for specialist dealers in the fields of agricultural technology, garden and forestry, construction machinery, hydraulics and industrial trucks. If you have any questions, don’t hesitate to get in touch. Give us a call on ✆ 01733 404920.